INTEGRAMplus Data Sheet

Microfluidic Pesticide Biosensor

Characteristics:

- The biosensor is based on silicon chip and acetylcholinesterase biomaterial.

- The sensitivity of the sensors is in the range of 10-9 M- 10-6 M.

- The sensor is reacting at organophosporus compounds that can be found in food, water, drugs, soil, vegetables, fruits.

- The answer of the sensor is fast and the overall preparation and measuring operation can be done in less of ½ hour.

|

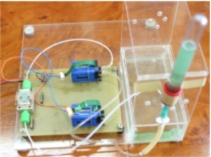

Microfluidic pesticide biosensor |

Overview

The biosensor is placed into the microfluidic module which allows the preparation of the sensor by injection of the electrolyte, the introduction of the sample and the electrical signal recording by using 4 spring probes connecting the biosensor pads with the measuring instruments.

IMT is offering the silicon chip, the electrolytes and the specifications for sensor preparation and measuring. The sensor is a consumable ones and needs to be removed after every detection step. According to customers requests the pH and temperature can be monitored inside the microchannels. A pH and a temperature sensor will be placed close to biosensor side.

EPIGEM is offering the microfluidic module hosting the silicon biochip. According to customer requirements a heating module will be developed by EPIGEM for keeping the sensor at 37°C during its life time.

IMT is offering the Labview interface and the microelectronics module for signal conditioning. The measurements will be computer controlled and data acquisition can be achieved.

|

Print screen of the Labview interface |

The system can be a useful tool for Food Inspection Laboratories (milk, water, juice, etc), Food industry, Pharmaceutical industry, Environment and Agriculture organizations, allowing fast detection, fast replacement of samples, data acquisition and data storage.

The system will be low cost, user friendly, precise and efficient.

Pesticide biosensor

The interdigitated electrodes surface is functionalised for biomaterial deposition in oxygen plasma, Plasma Etcher Etchlab 200, than Poly(ethylene glycol)300 (PEG): Ethanol (EtOH) 1:1 solution is deposited by adjustable air-displacement pipette (Gilson) 0,2 μL, as matrix for immobilized enzyme (AChE). The sensor was placed into a fluidic module which contains the electrical connections, injection and/or fluid transport and the reaction chamber with 2,5 μL volume, to ensure the measurements.

|

Silicon biochip into the microfluidic module,

pumps and reservoirs |

The silicon chip is based on interdigitated electrodes (Figure 3), 6mm x12 mm which are deposited with acetylcholinesterase enzyme.

Measurements

The impedimetric acetylcholinesterase (AChE) biosensor allows the detection of the pesticides by the enzyme blocking in the presence of pesticide in the sample near 10-6 M.

Example: Detection of Dichlorvos

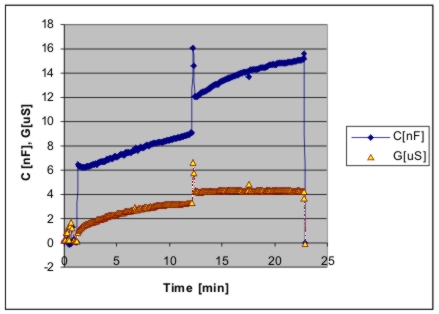

Acetylcholine iodide as substrate was injected and a clear and fast increase of the capacity and conductivity has been observed (Figure 3, point A). The evolution of the values was monitored for 10 minutes.

Then, it was injected an inhibitor solution, Dichlorvos 10-6M in the same electrolyte solution (Figure 3, point B), which remained in contact with the immobilized enzyme for the next 10 minutes.

|

Conductance and capacity versus time

A- substrate injection, B – inhibitor injection

|

After the injection of the inhibitor (insecticide Dichlorvos), measured values of the conductivity remained constant while the values of the capacity tend to be stabilized at the end of the measuring period. This demonstrates that the enzyme reaction was blocked by the presence of the studied insecticide.

For more information contact:

INTEGRAMplus

Office: +44 (0) 1684 896262

e-mail: info@INTEGRAMplus.com

Web: www.INTEGRAMplus.com

PRELIMINARY INFORMATION: This datasheet describes a product currently in development. INTEGRAMplus reserves the right to change specifications and details without notice.

© INTEGRAMplus 2008