back

L5: Simulation, Modelling and Computer Aided Design Laboratory

Head of the Laboratory: Dr. Raluca Muller

Interest in specific objectives and FP7 Calls:

- Objective ICT-2009.3.9: Microsystems and Smart Miniaturised Systems

- Objective FoF.ICT.2010.10-1: Smart Factories: ICT for agile and environmentally friendly manufacturing: a, b, c, d, e

- Objective GC.ICT.2010.10-3 ICT for the fully electrical vehicle ("ICT for Green Cars")

- FP7-NMP-2010-LARGE-4;

- FP7-NMP-2010-SMALL-4;

Main areas of expertise:

-

design, development and optimization of MEMS/MOEMS components and devices (switches, cantilevers, bridges, membranes, microgrippers); mechanical, thermal, electrical and electrostatic, piezoelectric, fluidic, as well as coupled field (static and transient) analysis; modeling and simulation for multi-physics problems; design, modelling and simulations of microfluidic components and systems for biomedical applications and micro-electronic fluidic - the microfluidic analyzes include: fluid dynamics in microstructures ; electrokinetic with field switching analysis; fluid diffusion; bubble and droplet simulation (transport, merging, splitting); interaction between fluids and mechanical parts; mechanical, electrostatic, piezoelectric analysis for microfluidic actuators-; modelling of optoelectronic devices, neural networks.

-

elastomer based microstructures (technology, applications); optical processing and storage of information; micro-systems applications in the field of energy; manufacturing and characterization of materilas for advanced nanoelectronic devices based on oxidic materials; techiques of chracterizations as cathodoluminescence and photoluminecence

Participation in International co-operations

-

FP6: MI-Lab on chip- “Lab-on-a-chip implementation of production processes for new molecular imaging agents- STREP (2005-2008), NMP-No 516984; coordinator University of Liege, Belgium

-

FP 6: IPMMAN: Improvement of industrial Production Integrating Macro, Micro And Nanotechnologies for more flexible and efficient manufacturing FP 6 Project (CA, NMP-CT-033205, 2006-2009): Coordinator Profactor, Research and Solutions GmbH, Austria ComEd: Leonardo da Vinci - Life Long Learning Development of competences of educational staff by integrating operational tasks into measures of vocational training and further education” – ComEd (2008-2010); Coordinator BWAW Thüringen gGmbH, Germany, Contract Number : DE/08/LLP-LdV/TO/147174- ( 2008-2010)

Specific facilities

Soft/hard Tools:

- COVENTOR 2008.2 (Architect, FlowMM; MemHenry; MemPackage; Designer; Analyzer Std., Microfluidics; MemOptics, Semulator, EM3DS)

- MATLAB 7: Optimization Toolbox; Extended Symbolic Math Toolbox; Partial Differential Equation Toolbox; Genetic Algorithm and Direct Search Toolbox; Statistics Toolbox; Neural Network Toolbox; Curve Fitting Toolbox; Spline Toolbox; Signal Processing Toolbox; Image Processing Toolbox; Simulink

- ANSYS Multiphysics 11.0- Structural, thermal, acoustic, electromagnetic and coupled field analyses, CFD

- COMSOL Multiphysics 3.3 and 3.4 (enabling parallel computation)

- Solidworks Office Premium 2008 - 3D CAD design software

- Mathematica 7 Mathematical software for technical and scientific data processing

- Origin PRO 8: data analysis and graphing workspace, analysis tools for statistics, 3D fitting, image processing and signal processing

- Visual Studio 2008 Pro Programming tool for RAD and IDE.

- Dual IBM 3750 Server with 8 quad-core Intel Xeon MP 2.93 GHz processors, 196 GByte RAM and 1 TByte HDD + 876 GByte external storage

- Computer network for training

Characterization equipments

- Avantes Fiber Optic Spectrometer - AvaSpec NIR256-2.2 - The AvaSpec equipment is used in optical specra aquisition and characerization of thin fims luminescence emission.

- Fluoreecence spectrometer in UV-vis-NIR, also for reflection, transmission and absorption

- Reflective conoscope

- Semiconductor Characterization System (4200S/C/Keithely) with Manual Probe Station (EP6/SüssMicroTec).

Processing equipments:

Dip Pen Nanolithography system-allows pattering in nanometric range and is a direct writing method that can use molecular and biomolecular “inks” on a variety of substrates.

2 Laboratories: National projects Capacities

- LABORATORY FOR MODELING AND SIMULATION OF MICROSYSTEMS -LAMSYS (2007-2009)

Project Type: PN II- Capacities; Contract no.7/2007

Project manager: Mat. Oana Tatiana Nedelcu- (oana.nedelcu@imt.ro)

- INTEGRATED LABORATORY OF ADVANCED TECHNOLOGIES FOR MICRO AND NANOSYSTEMS - MICRONANOLAB (2007-2009)

Project Type: PN II -- Capacities Contract no.13 / 2007 - Project manager: Dr. Gabriel Moagăr-Poladian (gabriel.moagar@imt.ro)

Service offer

- We provide access and consultancy to soft and hardware facilities for solving different research problems for industry and academia;

- We organized and provide access to the training network for seminars, courses, labs for students;

Simulation, consulting and training services in micro and nano domains;

Application areas: microsensors, microfluidics, MEMS/NEMS, MOEMS, RF MEMS

|

|

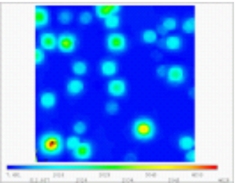

|

|

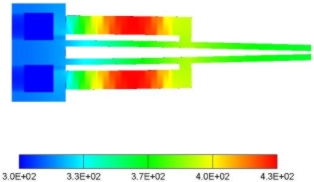

ANSYS |

COVENTOR |

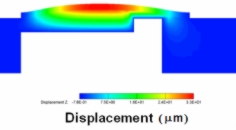

COVENTOR |

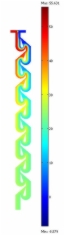

COMSOL |

- Computer Aided Design using dedicated software tools: COVENTOR 2008 and ANSYS

- Mask Design, Process Editor, 3D building and mesh

- Modeling for technological processes/ optimizations

- Special features: particularized use (macro or subroutine) creation; special geometrical modeling (AFM images reconstruction in CAD format, surfaces generated in accordance with mathematical expression, etc)

- Computer Aided Engineering and Analysis (using FEM, FVM, BEM tools)

- Microfluidics analysis (thermo)dynamics, electrokinetics, diffusion, fluid mixing and separation in microcomponents

- Electro-thermo-mechanical and piezoelectric analysis (steady state and transient).

- Coupled field simulations: thermo-mechanical simulations; electro-mechanical simulations; multiphysics, fluid-solid interaction

- Consultancy regarding design and simulation optimization

- Training in COVENTOR COMSOL and ANSYS using training dedicated infrastructure

|

| |

|

|

|

HOME |

|

Last update: August, 2009 |

|